WE AIM TO SERVE

Avoid Costly Downtime with Our Free High-Pressure Compressor Checklist

Protect your breathing-air or industrial compressor with our proven 5-step preventative maintenance guide.

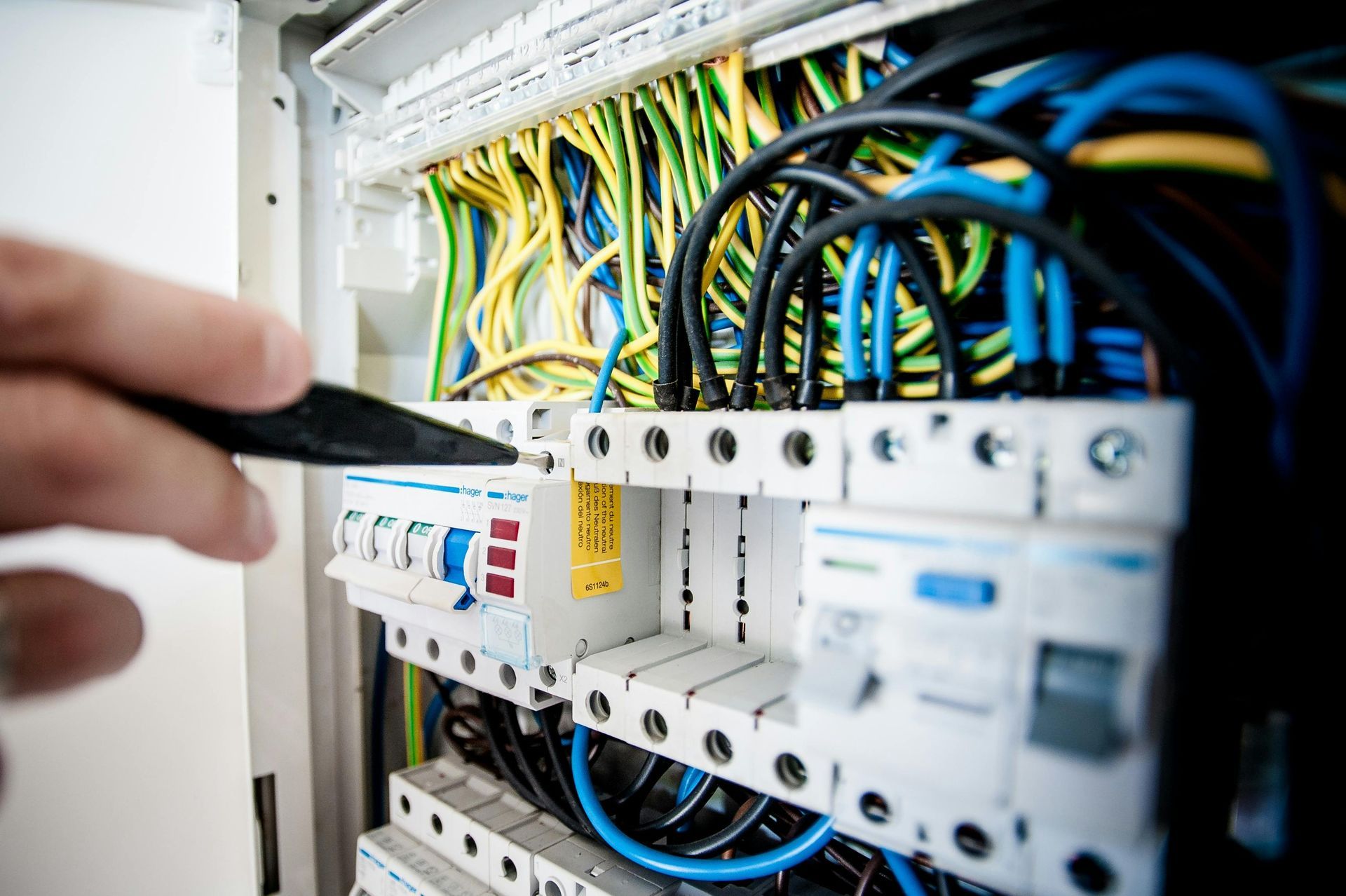

High-Pressure Air Systems Are Expensive to Replace- They Shouldn’t Be Neglected!

Your high-pressure compressor is mission-critical. Whether you’re running a fire station, a dive shop, or an industrial facility—downtime can mean more than lost revenue. It’s a safety and compliance risk!

That’s why we created this free, practical maintenance checklist to help you:

- Catch issues before they cost you thousands

- Protect your Bauer or rebuilt compressor investment

- Maintain performance and uptime year-round

Trusted by Breathing-Air and Industrial Clients Worldwide

For over a decade, Compressed Air Partners has rebuilt, installed, and maintained hundreds of Bauer and other High Pressure Air and Gas Systems for municipalities, military units, dive shops, fire departments, and manufacturing clients.

We know what fails—and how to stop it before it does.

“Compressed Air Partners has saved us thousands by preventing shutdowns. Their insight and service plans are top-tier.”

— SCUBA Diving Park Operator, AL

This Simple 5-Step Checklist will help you and your team:

- Spot pressure leaks before they become emergencies

- Keep lubricants at optimal levels

- Maintain clean, breathable air quality

- Avoid overheating and compressor failure

- Track key inspection items on a recurring schedule

Designed for facility managers, operators, and safety directors.

Easy to complete with minimal loss of production!